A compact device intended for cleaning of rinsing and waste waters containing waterborne paints, emulsions and adhesives.

The device works in semi-automated operation.

Performance: approx. 100 – 200 litres / 1 hour.

The device is designed for operations with a small production of waste waters.

Function of the device

1st Cleaning phase

Rinse water is pumped into the reactive part of the device. The process of mixing is initiated on the control panel. This causes homogenization of pumped waste water.

2nd Cleaning phase

During mixing, the relevant quantity of proposed reactive product is dosed manually. The mixing process automatically ends after about 10-15 minutes and the sedimentation process starts.

3rd Cleaning phase

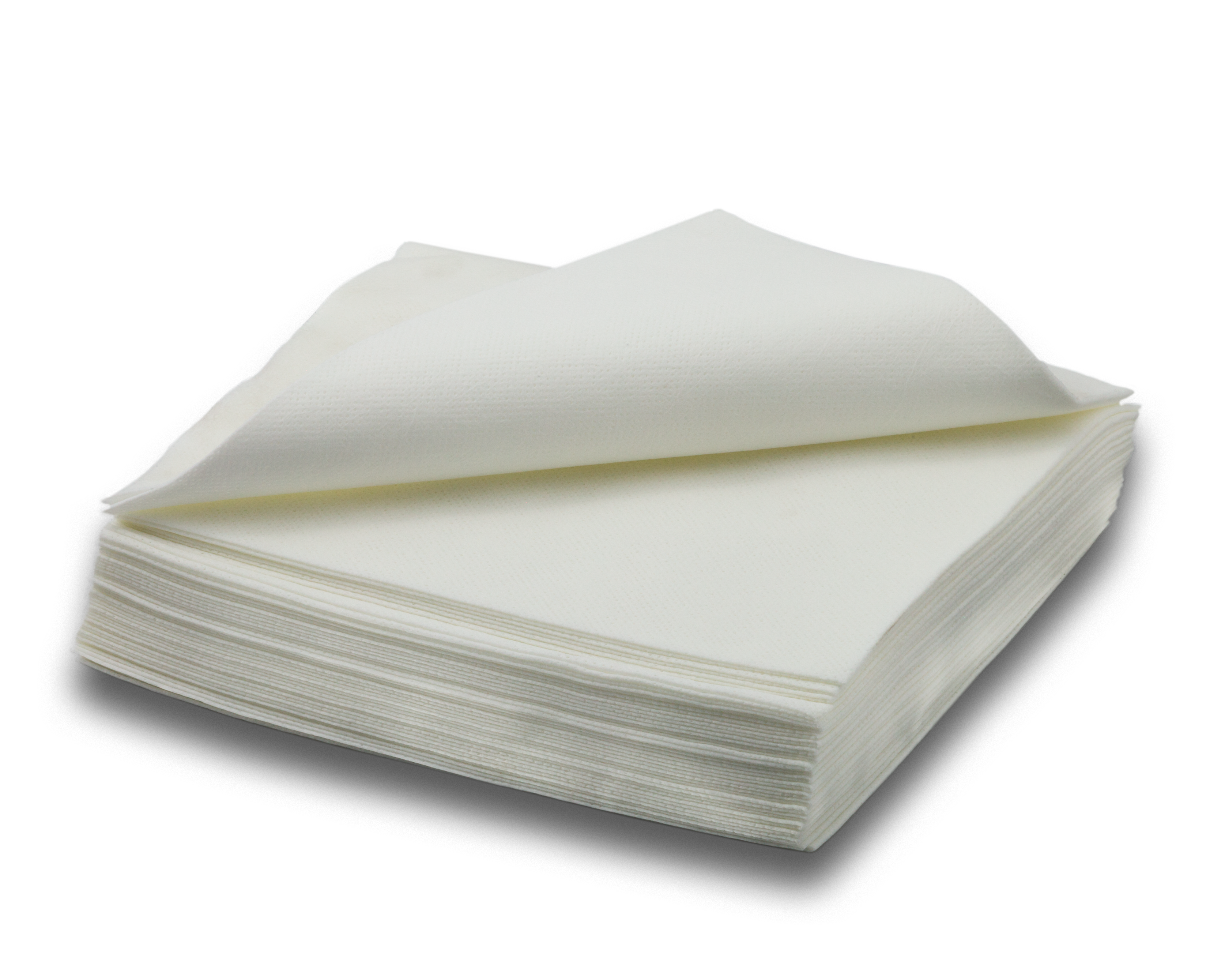

After the end of sedimentation (approx. 10 minutes), the draining ball valve PVC DN 50 mm is opened. The entire volume of the reactive part is released through the draining boxes with a filtration bag. Cleaned water is automatically pumped to the sewerage system. The captured sludge is thoroughly drained in the filtration bag after about 30 minutes.

(*) - Performance of the device is dependent on the level of pollution of the waste water

(**) - Weight of the device is shown without the medium.