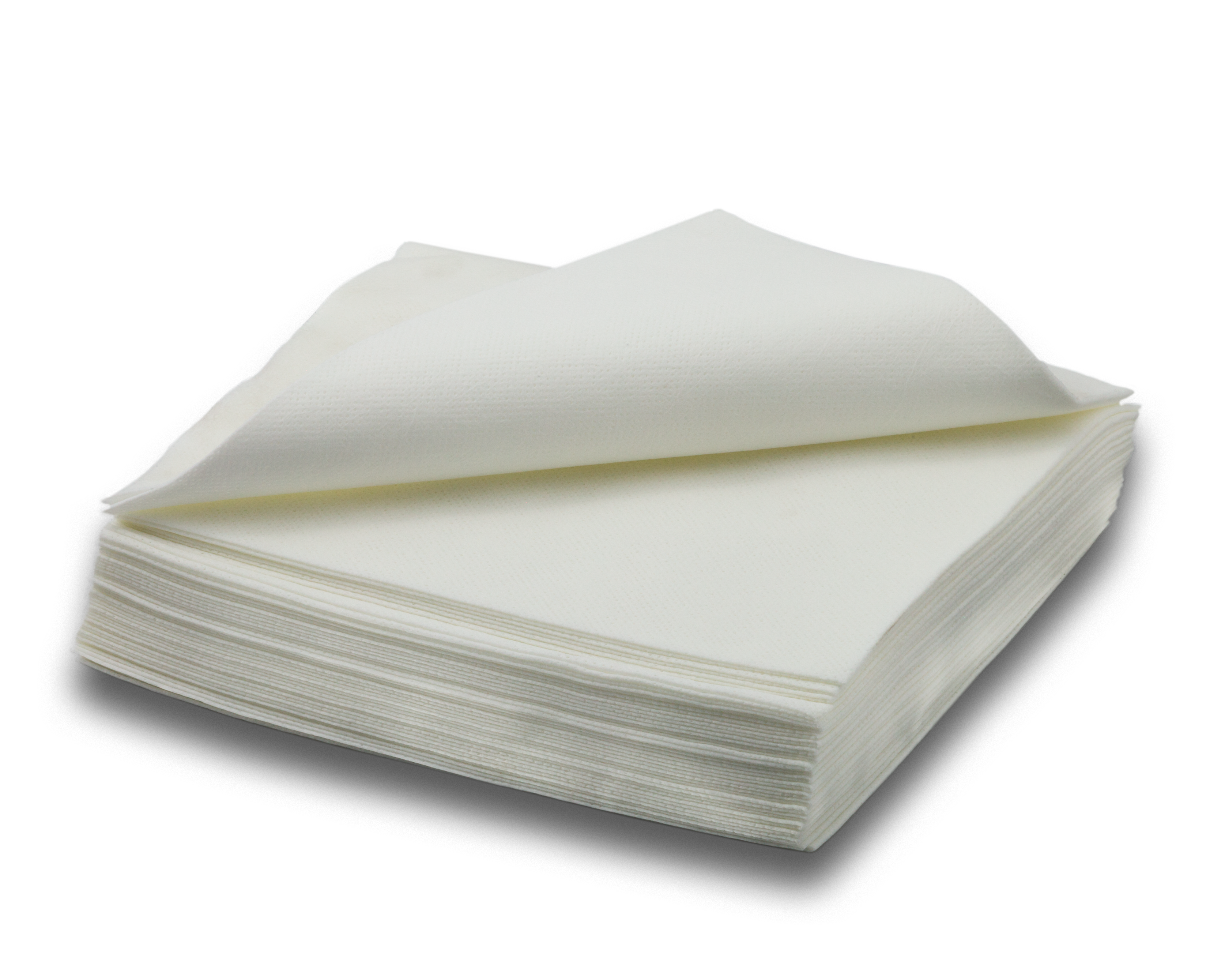

The bag filter consists of the front fixing frame and several filter bags. Individual bags are of wedge-shaped design and they are made of micro glass fleece. Distant threads ensure full-scale use of the depth of the bag and thus also overall filtration area. Filter bags are fixed into the stable frame of U-profile (height of 25 mm) by using glue and fixing elements. Frames are made of zinc-plated metal sheet or from the plastic profile.

Field of use

Bag filters are used for fine filtration with high level of arrestance.

Examples of use

- Ventilation and air-conditioning systems of industrial companies, public buildings, schools, sport halls.

- Ventilation and air-conditioning equipment for laboratories, hospitals, chemical and pharmaceutical production plants

- Air inlet for spray booth and ventilation of airport lounges

Advantages of use

- Bag filter with a plastic frame can be fully burnt after its exchange

- Full-scale use of the bag´s depth ensures high dust capture capacity

- Wide assortment of standard design of the bag filter with ten sizes of front frames

Other options of design

- Antistatic – version for explosive environment, marking EX

- SepTex – antibacterial and anti-fire version

Technical data is related to the standard size of the filter 592x592 mm and standard number of bags.