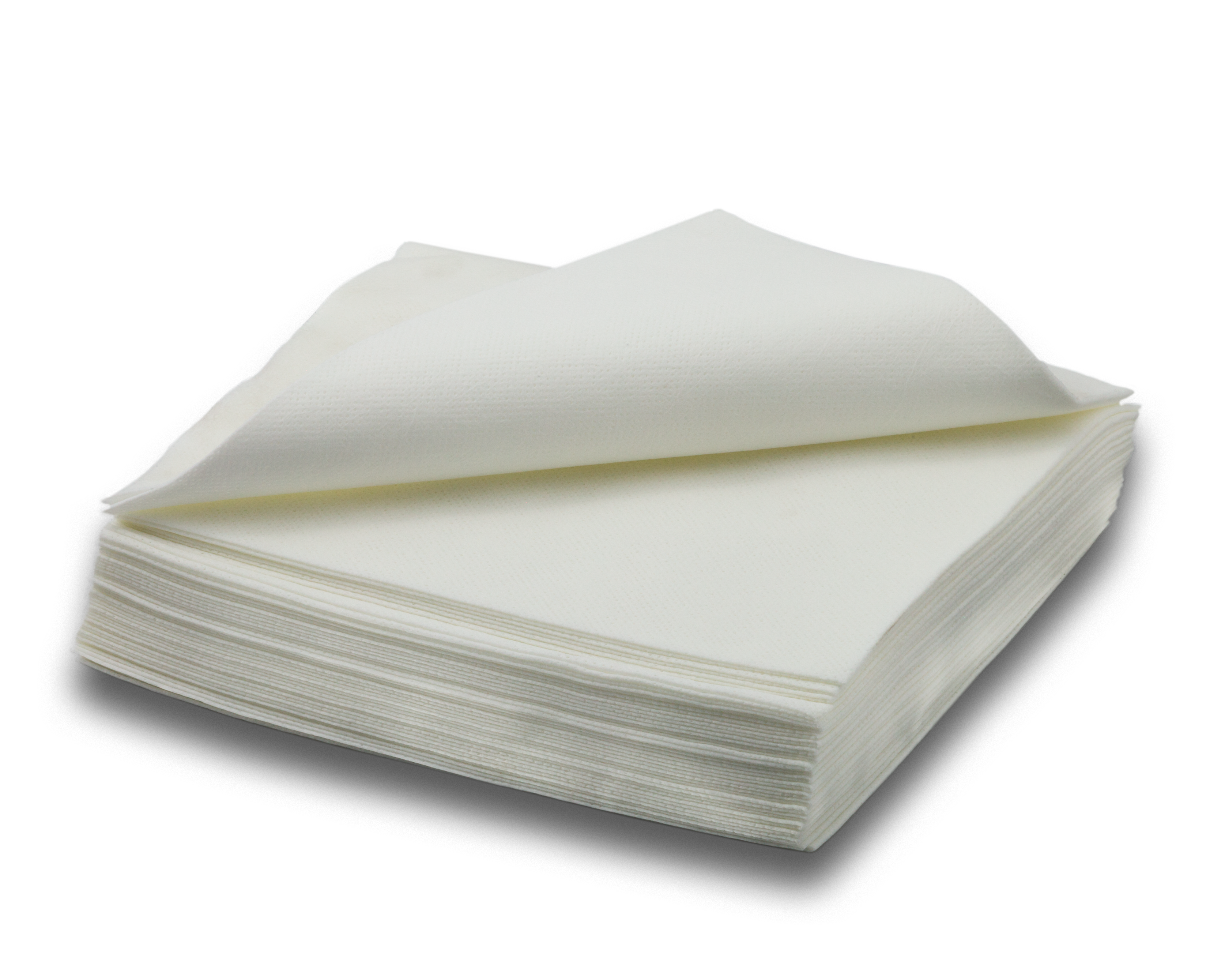

The base of the filter insert is the filter medium in the form of special filtration papers made of glass sub-micron fibres.

This filtration paper is folded into a stable thread, whose optimal number and height of folds with respect to the operating point of the filter ensures the required filter class and long lifespan of the filter insert. The paper is separated by hot-melt beads.

Filtration thread is hermetically sealed into a stable, torsion-resistant filter frame, which along with the endless sealing made of PUR foam, guarantees quality-sealing of the filter insert in mounting cabinets. This filter structure is the base for compliance with high requirements for air purity. The basic frame material is MDDF. On request, the frame filter can be made also of zinc-plated and steel, stainless steel or aluminium metal sheets.

Field of use

- Medicine

- Microbiology

- Chemical industry

- Pharmaceutical industry

- Food-processing industry

- Electrical engineering industry

- Nuclear technology

Examples of use

This highly efficient filter insert with higher arrestance against all types of aerosols is used as an end filter of multi-level filtration in air-conditioning and ventilation devices, for cleaning of inlet and outlet air in technologically demanding processes and for purification of air from harmful dust, viruses, and bacteria in hospital facilities.

Advantages of design

- High mechanical stability

- Optimal structure of folded thread

- Steady outlet airflow velocity

- Various types of frame and sealing materials

Delivery

- Standard installation depth: 46, 54, 69, 78, 150, 292 mm

- Frame material: aluminium, stainless steel, MDF, plywood

- Type of sealing: foamed PUR, flat rubber, U-profile

- Sealing position: inlet, outlet